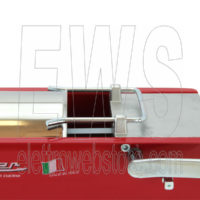

Reber 2-speed manual bagging machine red

137,00€ – 375,00€ VAT included

Manual bagging machine with bagging tube made of 18/10 stainless steel for food use AISI 304. Red painted steel outer frame. Patented venting ring to facilitate the escape of air. Capacities to choose from: 3 litres, 5 litres, 6.8 litres, 10 litres, 12 litres. Free shipping in Italy for orders over 100 Euro

Reber manual bagging machine 2 speeds RED

Reber red 2-speed manual bagging machine is a product for making sausages at home.

Through this advertisement you can choose bagging machine models with a red painted steel frame. If you are interested in the Reber bagging machines with AISI 430 stainless steel outer frame, you can visit this page.

Conversely, you can also consider buying the vertical stainless steel fillers, which can also be used horizontally.

In this advertisement you will find a choice of all models in this range. In fact, to make your selection, simply choose the model you are interested in from the menu above. All available models are as follows:

- 8956N - Reber 2-speed bagging machine kg.3, 3 litres

- 8950N - Reber 2-speed bagging machine kg.5, 5 litres

- 8951N - Reber 2-speed bagging machine kg.8, 6.8 litres

- 8953N - Reber 2-speed bagging machine kg.10, 10 litres

- 8954N - Reber 2-speed bagging machine kg.12, 12 litres

Description of Reber bagging machines

All red 2-speed manual bagging machines are made with a painted steel frame.

They are also equipped with metal gears to reduce and multiply the speed of the piston, in order to facilitate and speed up bagging operations (slow) and piston extraction at the end of the job (fast).

All fillers are equipped with an AISI 304 stainless steel tube, square bar steel rack for a larger gripping surface, nylon piston support, piston cover and gasket made of plastic material suitable for contact with foodstuffs.

Reber's bagging machines are also equipped with a set of four bagging funnels for all types of sausages (diameter approx. 16-22-30-40 mm).

How to use a Reber bagging machine

The Reber manual sausage filler is a tool used to fill casings (natural or synthetic) with minced meat for the production of sausages or other sausage products.

You can follow these simple steps to get the most out of your Reber 2-speed manual bagging machine with red painted frame.

1. Preparation of Ingredients and Equipment

Preparing the fillingmince meat (usually pork, beef, chicken, or a combination) with spices, salt and other ingredients such as garlic, pepper, wine or herbs, depending on the recipe. The meat should be well mixed and ready to be placed in the filler cylinder.

Preparing the casingIf you use natural casings (such as pork casings), you will have to soak them in warm water to soften and clean them. If you use synthetic casings, these are usually ready to use.

Positioning the bagging machineFix the bagging machine on a stable, flat surface, such as a work surface or table.

2. Assembling the Bagging Machine

Connect the casing tubeInsert the end of the casing onto the nozzle or tube of the filler. The nozzle must be of an appropriate size for the type of casing you are using. With the Reber filling machine you have 4 different types of funnels to choose from.

Check the pistonMake sure that the piston inside the cylinder is positioned correctly and that the manual mechanism (crank) operates smoothly.

3. Filling the Bagging Machinee

Place the filling in the filling tubeLoad the minced meat into the filler cylinder, taking care not to compress the filling too much, so that the flow is not obstructed.

Carefully position the pistor. After filling the sausage tube, carefully place the peaker on the meat, trying to make sure the air is removed.

Place the casingSlide the casing over the nozzle, taking care not to let any air enter the casing, otherwise air bubbles may form during stuffing.

4. Bagging the Meat

Crank the crank at slow speedStart turning the crank to push the meat through the cylinder and into the casing. Be careful not to force the movement to avoid breaking the casing. Proceed slowly and steadily for even filling.

Check pressureWhen the casing fills, keep a slight tension to prevent too much air from forming. If you see air bubbles, you can remove them gently with a pin.

Stretching the casingAs the filling enters the casing, allow it to flow without letting it become too swollen. It is advisable to stop occasionally to stretch the casing so that it fills evenly.

5. Tying and sealing the casing

Close each sausageOnce the casing is filled, tie it with string at regular intervals to create the individual sausages. You can also use ties to tie the ends of the casing.

Remove any air bubblesUsing a pin, gently pierce the air bubbles that have formed in the casing during the stuffing process.

6. Cleaning and Storage

Remove the casing from the nozzle: Once the sausage has been filled using the Reber filling machine, carefully remove the casing from the tube.

Cleaning the bagging machine: After each use, disassemble the vacuum filler and clean it thoroughly with warm soapy water, using a brush to remove any meat residue. Make sure that all parts are well dried before storing the vacuum filler.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Capacity | 3 kg-3 l, 5 kg-5 l, 8 kg-6.8 l, 10 kg-10 l, 12 kg-12 l |