Reber professional stainless steel and red vertical bagging machines

178,00€ – 559,00€ VAT included

Reber professional vertical bagging machines equipped with 4 bagging tubes. They can operate vertically and horizontally for meat, sausages, casings. The 3 litre and 5 litre versions are also available with a red painted steel frame.

Reber professional stainless steel and red vertical bagging machines

Reber professional stainless steel and red vertical fillers can be operated either horizontally or standing upright. The 3-litre and 5-litre versions are also available with a red painted steel frame.

They are designed for those who have special space requirements and need to bag large quantities of product.

The package contains 4 bagging tubes made of plastic suitable for food contact with the following diameters: 1 cm, 2 cm, 2.5 cm and 3.5 cm

The gearbox at the rear is sealed. This prevents dirt and food residues from coming into contact with the gears.

You can visit the Reber page for further product and warranty information. In addition, you can visit the page on bagging machines to know all the technical details on how these machines work and how to use them.

Professional machines are assembled especially for the customer. The right of withdrawal for cooling-off is excluded for such machines.

Technical specifications

- Capacity: 5 l, 6.8 l (8 l designation), 10 l, 12 l.

- Speed: 2

- Slow forward gear, fast reverse gear for greater convenience and speed of use

- Front air vent without the use of valves on the piston (Reber patented system)

- AISI 430 stainless steel supporting structure (can stick to magnet proof)

- AISI 304 stainless steel tube suitable for food contact

- Steel reduction gears and piston speed multiplication to facilitate and speed up bagging operations (slow) and piston extraction at end of work (fast)

- Gear guard

- Dual mode of use: vertical and horizontal

- 4 bagging funnels of different sizes supplied as standard diameters: 1 cm, 2 cm, 2.5 cm and 3.5 cm

- Manual operation by hand crank

Description

Reber bagging machines are robust and reliable machines built using the most modern technological solutions and the most appropriate materials that comply with current food contact regulations.

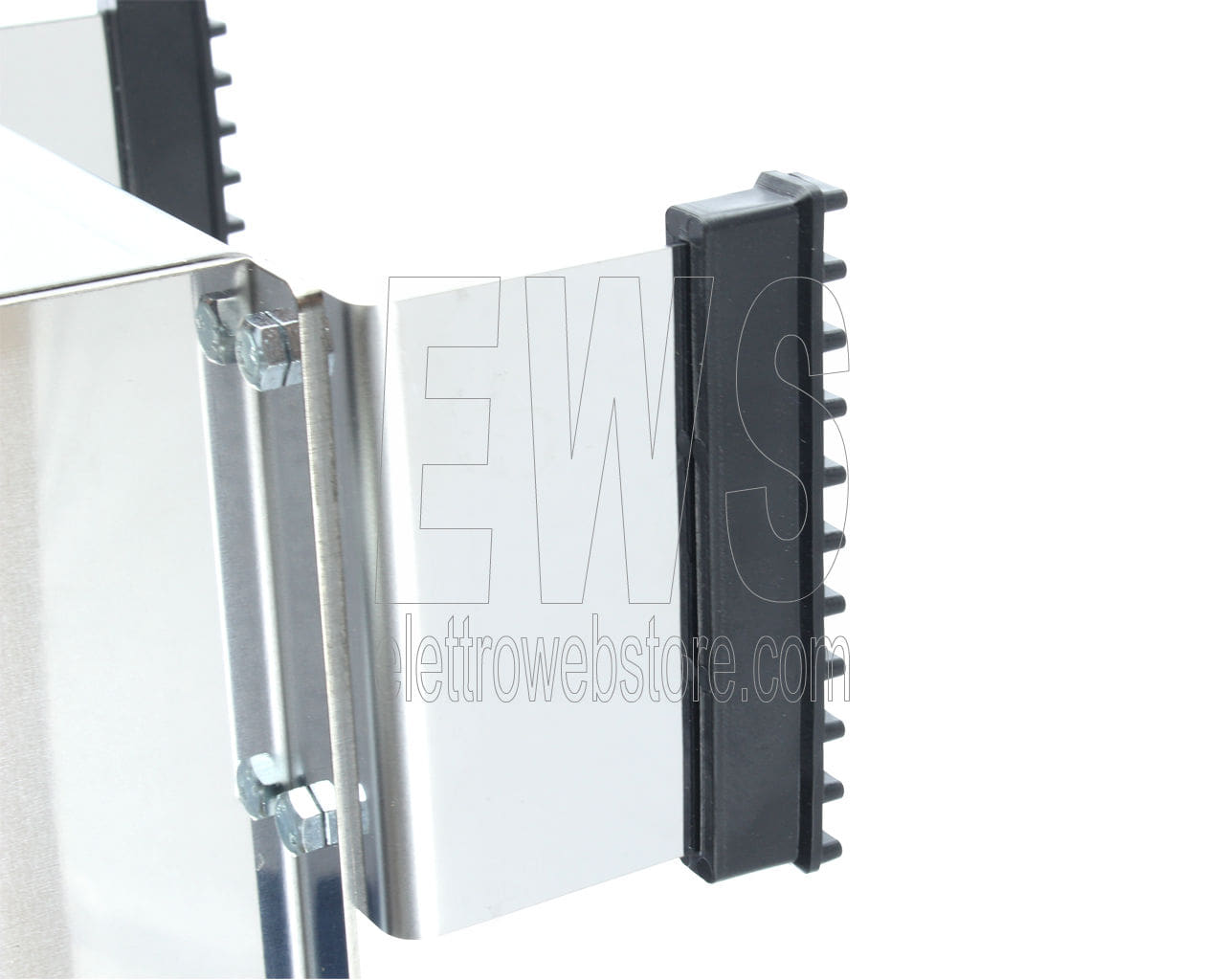

All models are equipped with the Reber's patented front air vent system. In fact, this system allows the air to pass directly through the ferrule and funnels that have grooves at the base to act as a vent.

Reber Vertical/Horizontal Bagging Machines are designed to optimise the possible uses of a bagging machine; with just one machine it is possible to bag in both positions, vertically for more liquid dough and horizontally for dry dough.

L'bagging funnel is made of AISI 304 stainless steel which is suitable for food contact because it is low in carbon. It also passes the magnet test, i.e. if you try to stick the magnet, it does not stick.

The structure of the bagging machine is made of AISI 430 stainless steel.i.e. still stainless steel but with a somewhat higher carbon content.

This bagging machine model is part of the professional line, i.e. it has the rack with steel gears which are also protected by a box, also made of stainless steel, which preserves them from dust and food residues and improves their functionality.

It is also equipped with a convenient front handle for any displacements.

Vertical models are supplied already prepared for vertical bagging (with the acetal resin bend already fitted).

When used in horizontal mode, it is equipped with sturdy steel feet covered with toothed plastic materialto improve stability.

To use the filler in horizontal mode, simply unscrew the acetal resin bend and remove the gasket and mount in its place one of the 4 supplied filler funnels and screw on the ring nut.

Uhe use of the ring nut with grooves always allows the best utilisation of Reber's patented air expulsion system, thanks to the combined action of the grooves on the ring nut and the serrations on the filling funnels.

The bagging tube made of AISI 304 stainless steel is completely removable and washable. Once filled and repositioned, you can start bagging by turning the crank. The second pin is for fast feeding.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| capacity | 3 lt red, 5 lt red, 3 lt stainless, 5 lt stainless, 6.8 lt stainless, 10 lt stainless, 15 lt stainless |