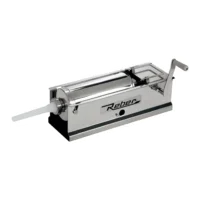

Reber professional manual stainless steel bagging machine

225,00€ – 559,00€ VAT included

Reber professional manual stainless steel 2-speed bagging machine with 18/10 AISI 304 stainless steel bagging tube. AISI 430 stainless steel casing. Capacity 3 litres, 5 litres, 6.8 litres, 10 litres, 12 litres, 15 litres. Made in Italy

Reber professional manual stainless steel 2-speed bagging machine

Reber professional manual stainless steel 2-speed bagging machines are manually operated bagging machines designed for intensive use.

Compared to the Reber standard stainless steel bagging machines or to the Reber bagging machines with painted construction they are equipped with a gearbox casing. In this respect, therefore, they belong to the professional category like the Reber vertical bagging machinesi.

In addition, all professional bagging machines are equipped with steel gears.

The package contains 4 bagging tubes made of plastic suitable for food contact with the following diameters: 1 cm, 2 cm, 2.5 cm and 3.5 cm

You can visit the Reber page for further product and warranty information. In addition, you can visit the page on bagging machines to know all the technical details on how these machines work and how to use them.

Professional machines are assembled especially for the customer. The right of withdrawal for cooling-off is excluded for such machines.

Description

Le Reber professional stainless steel bagging machines with steel gears and gear body casing are high-quality tools used in the food industry for filling sausages, such as sausages and salami, into natural or artificial casings.

These models are designed for high performance, strength and durability, meeting the demands of intensive professional production.

Structure and materials

- Stainless steel body: The body of Reber's bagging machines is made entirely of stainless steel, a material that is highly resistant to corrosion and chemicals and guarantees a long service life even in wet working environments and in contact with food. Stainless steel is easy to clean and sanitise, a key aspect in maintaining high standards of food safety.

- Steel gears: The gears that control the operation of the machine are made of steel, which ensures robustness and precise operation. The use of steel ensures high wear resistance, improving the efficiency and longevity of the machine.

- Gear casing: The fairing that protects the gears is designed to be durable and protective, reducing the risk of contamination and damage to internal parts. In addition, the fairing helps to keep the noise level during operation at a low level, making the bagging machine quieter and safer to use.

Operation and capacity

Reber professional sausage fillers are designed for fast and precise filling. The filling is inserted into the casing by means of a piston with a special seal, which uses the force of the gears to dose the material correctly.

The capacity of these machines varies depending on the model, with bagging tubes that can hold up to 15 litres of dough, and are ideal for medium or large productions, such as those of butcheries, delicatessens and food industries.

Additional Features

- Simplified maintenance: Removable parts and smooth surfaces make cleaning and routine maintenance very easy, ensuring a hygienic environment at all times.

- VersatilityReber's sausage fillers are compatible with a variety of nozzles and accessories, enabling the production of different types of sausages, such as fresh sausages, salami or frankfurters.

- Ergonomic design: The machines are designed to be intuitive and convenient, with easily accessible controls and smooth operation. Some models are also equipped with wheels for easy movement.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Capacity | 3 kg-3 l, 5 kg-5 l, 8 kg-6.8 l, 10 kg-10 l, 12 kg-12 l, 15 kg-15 l |